1 Conas calafort flange ISO 6162-1 agus ISO 6162-2 a aithint

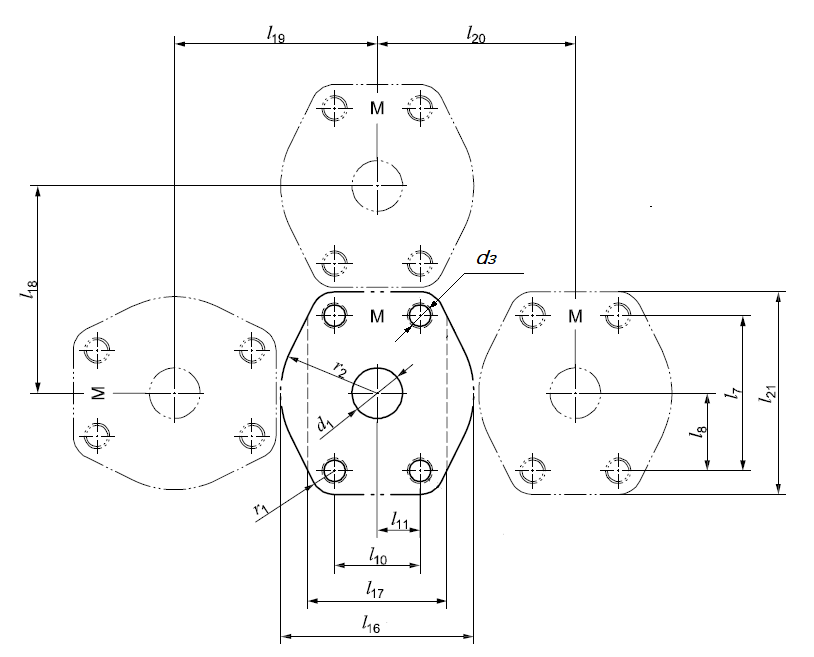

Féach tábla 1 agus figiúr 1;

Tábla 1 Toisí calafoirt flange

| Méid flange | Toisí calafoirt flange | ||||||||

| ISO 6162-1 (SAE J518-1 CÓD 61) | ISO 6162-2 (SAE J518-2 CÓD 62) | ||||||||

| méadrach | Fleasc | l7 | l10 | d3 | l7 | l10 | d3 | ||

| Scriú méadrach | Scriú orlach | Scriú méadrach | Scriú orlach | ||||||

| 13 | -8 | 38.1 | 17.5 | M8 | 5/16-18 | 40.5 | 18.2 | M8 | 5/16-18 |

| 19 | -12 | 47.6 | 22.2 | M10 | 3/8-16 | 50.8 | 23.8 | M10 | 3/8-16 |

| 25 | -16 | 52.4 | 26.2 | M10 | 3/8-16 | 57.2 | 27.8 | M12 | 7/16-14 |

| 32 | -20 | 58.7 | 30.2 | M10 | 7/16-14 | 66.7 | 31.8 | M12 | 1/2-13 |

| 38 | -24 | 69.9 | 35.7 | M12 | 1/2-13 | 79.4 | 36.5 | M16 | 5/8-11 |

| 51 | -32 | 77.8 | 42.9 | M12 | 1/2-13 | 96.8 | 44.5 | M20 | 3/4-10 |

| 64 | -40 | 88.9 | 50.8 | M12 | 1/2-13 | 123.8 | 58.7 | M24 | - |

| 76 | -48 | 106 | 61.9 | M16 | 5/8-11 | 152.4 | 71.4 | M30 | - |

| 89 | -56 | 121 | 69.9 | M16 | 5/8-11 | - | - | - | - |

| 102 | -64 | 130 | 77.8 | M16 | 5/8-11 | - | - | - | - |

| 127 | -80 | 152 | 92.1 | M16 | 5/8-11 | - | - | - | - |

Fíor 1 Toise an chalafoirt do naisc flange

Ó tábla 1, méideanna Dash-8 agus -12, tá sé toisí scriú céanna agus go dlúth l7 agus l10 le haghaidh ISO 6162-1 agus ISO 6162-2, mar sin ní mór na toisí l7 agus l10 a iniúchadh go cúramach, agus a thomhas le cruinneas 1 mm nó níos lú.

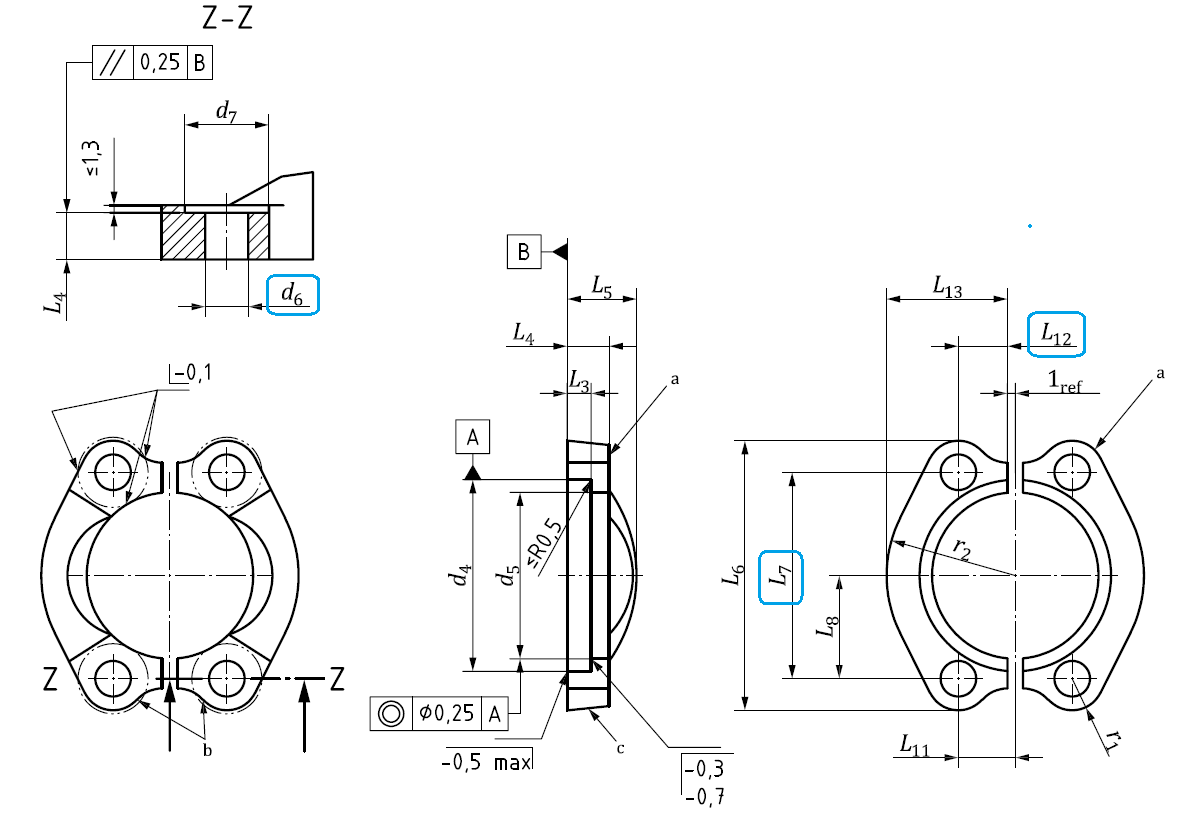

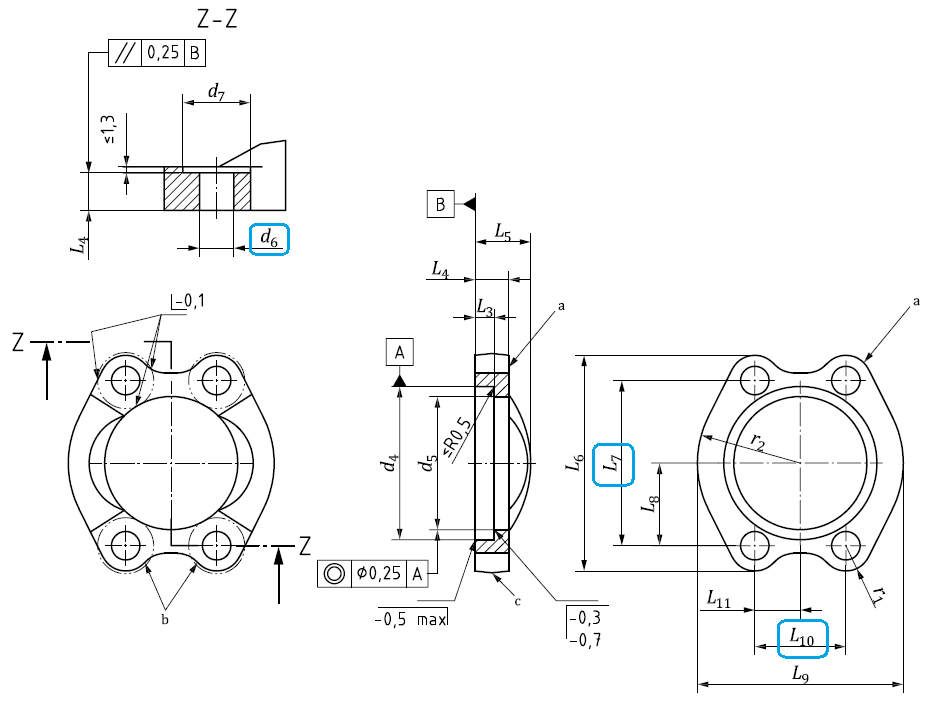

2 Conas clamp flange ISO 6162-1 agus ISO 6162-2 a aithint

Féach tábla 2 agus figiúr 2, figiúr 3, déan comparáid idir na príomhtoisí le haghaidh clamp flange aitheantais ISO 6162-1 (SAE J518-1 CODE 61) nó clamp flange ISO 6162-2 (SAE J518-2 CODE 62).

Más clampán flange scoilte é, iniúchadh agus cuir i gcomparáid le toisí l7, l12 agus d6.

Más clampán flange aon-phíosa é, déan toisí l7, l10 agus d6 a iniúchadh agus a chur i gcomparáid.

Tábla 2 Toisí clamp flange

| Méid flange | Toisí clamp flange (mm) | ||||||||

| ISO 6162-1 (SAE J518-1 CÓD 61) | ISO 6162-2 (SAE J518-2 CÓD 62) | ||||||||

| méadrach | Fleasc | l7 | l10 | l12 | d6 | l7 | l10 | l12 | d6 |

| 13 | -8 | 38.1 | 17.5 | 7.9 | 8.9 | 40.5 | 18.2 | 8.1 | 8.9 |

| 19 | -12 | 47.6 | 22.2 | 10.2 | 10.6 | 50.8 | 23.8 | 10.9 | 10.6 |

| 25 | -16 | 52.4 | 26.2 | 12.2 | 10.6 | 57.2 | 27.8 | 13.0 | 13.3 b |

| 32 | -20 | 58.7 | 30.2 | 14.2 | 10.6 a | 66.7 | 31.8 | 15.0 | 13.3 |

| 38 | -24 | 69.9 | 35.7 | 17.0 | 13.3 | 79.4 | 36.5 | 17.3 | 16.7 |

| 51 | -32 | 77.8 | 42.9 | 20.6 | 13.5 | 96.8 | 44.5 | 21.3 | 20.6 |

| 64 | -40 | 88.9 | 50.8 | 24.4 | 13.5 | 123.8 | 58.7 | 28.4 | 25 |

| 76 | -48 | 106.4 | 61.9 | 30.0 | 16.7 | 152.4 | 71.4 | 34.7 | 31 |

| 89 | -56 | 120.7 | 69.9 | 34.0 | 16.7 | - | - | - | - |

| 102 | -64 | 130.2 | 77.8 | 37.8 | 16.7 | - | - | - | - |

| 127 | -80 | 152.4 | 92.1 | 45.2 | 16.7 | - | - | - | - |

| a, 10.6 le haghaidh scriú méadrach, agus 12.0 le haghaidh scriú orlach | |||||||||

Fíor 2 Clamp flange scoilte

Fíor 3 Clamp flange aon-phíosa

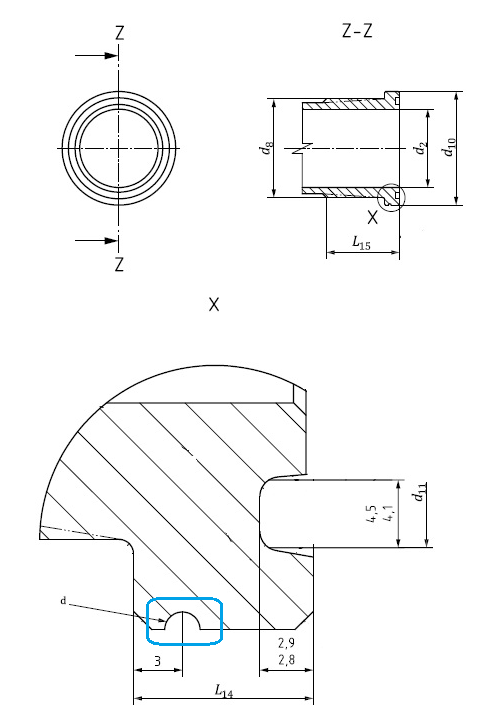

3 Conas ceann flange a aithint

Ó tábla 3 agus figiúr 4, déan comparáid idir na príomhthoisí le haghaidh ceann flange aitheantais ISO 6162-1 (SAE J518-1 CODE 61) nó ceann flange ISO 6162-2 (SAE J518-2 CODE 62).

Agus má tá groove aitheantais suite ar imlíne an diosca flange, féach figiúr 4 gorm marcáilte, is é ceann flange ISO 6162-2 é.(tá an marc seo roghnach roimhe seo, mar sin níl an marc seo ag gach ceann flange ISO 6162-2)

Tábla 3 Toisí ceann flange

| Méid flange | Toisí ceann flange (mm) | ||||

| ISO 6162-1 (SAE J518-1 CÓD 61) | ISO 6162-2 (SAE J518-2 CÓD 62) | ||||

| méadrach | Fleasc | d10 | L14 | d10 | L14 |

| 13 | -8 | 30.2 | 6.8 | 31.75 | 7.8 |

| 19 | -12 | 38.1 | 6.8 | 41.3 | 8.8 |

| 25 | -16 | 44.45 | 8 | 47.65 | 9.5 |

| 32 | -20 | 50.8 | 8 | 54 | 10.3 |

| 38 | -24 | 60.35 | 8 | 63.5 | 12.6 |

| 51 | -32 | 71.4 | 9.6 | 79.4 | 12.6 |

| 64 | -40 | 84.1 | 9.6 | 107.7 | 20.5 |

| 76 | -48 | 101.6 | 9.6 | 131.7 | 26 |

| 89 | -56 | 114.3 | 11.3 | - | - |

| 102 | -64 | 127 | 11.3 | - | - |

| 127 | -80 | 152.4 | 11.3 | - | - |

Fíor 4 Ceann flange

Am postála: Jan-20-2022